Curated Content Summary: 3D Scanning Technology can be very useful to use in a wide range of industries, automotive being one of them. Originally found on Artec3D this article written by Matthew McMillion discusses the reconstruction of a traffic accident using 3D scanning technology. By using the Artec Leo to scan cars in an accident, the scanned data enables an analysis of injuries as well as safety features of the car.

Every time forensic accident reconstruction expert Jarrod Carter, Ph.D., steps up to a twisted wreck, he sees a book of stories waiting to be told: how fast was the car moving when it slammed into the bridge? How many seconds before impact did the driver hit the brakes? Was everyone inside wearing their seat belts? And how well did the car’s safety features protect its occupants?

When helping to uncover a wreck’s story, Carter and his team collect diverse data, including 3D site models, police reports, and videos. They use drone photos, laser scanners, surveillance footage, dash cam recordings, and event data recorder information.

These varied sources offer up a broad spectrum of details from the seconds leading up to and including the crash: brake usage, accelerator application, steering wheel angle, lateral/longitudinal acceleration, roll rate, engine RPMs, gear positions, and more.

A recent addition to their storytelling toolbox is the Artec Leo.

Origin uses the Leo, a wireless handheld 3D scanner unlike any other, to tell the story behind the twisted metal that is a wrecked vehicle. Based on experience, they have found that the Leo can faithfully generate a digital twin of a vehicle’s exterior or interior in under an hour, from bumper to bumper, with submillimeter accuracy.

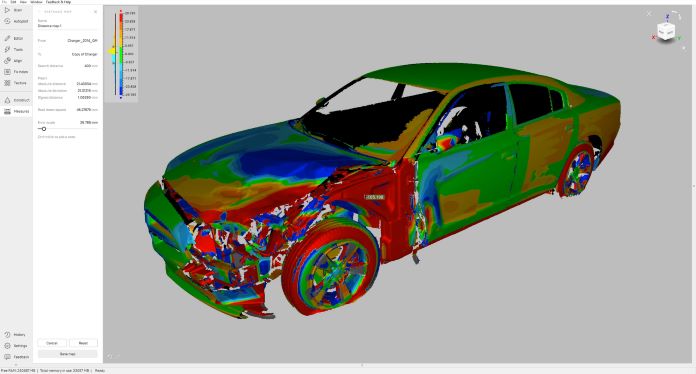

Artec Studio software screenshot showing the Leo scan of the 2014 Dodge Charger

In the past, as part of their push to create digital twins of wrecked vehicles, they used a tripod?mounted 3D laser scanner. The scanning process entailed physically repositioning the scanner numerous times around the vehicle, at multiple elevations, inside and out, to record as much detail as possible.

And, even with all the repositioning, the detail, while tremendously better than the plumb bob and tape measure method Carter used at the beginning of his career, was still lacking in the qualities necessary to create a convincing digital twin.

Another significant problem with the tripod-based laser scanner workflow was time. Each scan with a tripod-based scanner takes several minutes, not including the time associated with repositioning. A detailed scan of a vehicle could easily take an hour and, in some cases, as much as two or three hours.

Forensic Technician Kyle Rothwell scanning a wrecked 2014 Dodge Charger with Artec Leo (at Spalding’s Auto Parts in Spokane Valley, WA)

A brief window of time to scan the entire vehicle

When Carter and his team work, they typically have four to eight hours of access to a vehicle. Scanning is just one part of their agenda, and they treat their time with the vehicle as though it’s their last chance to inspect it. Any time saved during scanning allows them to ensure a complete inspection.

“This issue of time is why I searched for a better solution than our tripod-based laser scanner,” Carter said. “I wanted speed and flexibility, which Leo provides. It has no cables or attached computer to slow you down. Now, I don’t feel like the rest of the inspection is rushed just to make time for scanning.”

Jarrod Carter Ph.D., scanning a Dodge Minivan with Artec Leo (at Insurance Auto Auction in Puyallup, WA)

“Because the vehicle is at the very center of our work, it is important to spend enough time gathering the data needed for its digital twin, even when that took us a lot longer than it does today. Now, with Leo, we collect the data for the vehicle’s digital twin so much faster. And I can use the touchscreen on the back to check the quality of the 3D mesh it’s making, the texture being captured, to make sure I have what I need before I leave,” said Carter.

“If I missed some aspect of the vehicle or didn’t get the detail I wanted in an area, I can easily rescan the bit I’m interested in with a wave of the scanner. It’s not like in the past with our tripod-based laser scanning workflow, where we’d have to wait till we got back to the office and started processing the data before we realized that some texture or geometry was captured less than ideally. With Leo, when we walk away from the vehicle, we’re confident it’s all there.”

The crucial need for extensive, true-to-life textures

As it relates to the texture data, Carter expressed high praise for the Leo’s capability, “What we weren’t expecting with Leo was the fidelity of the texture information it captures. The color and surface details appear photorealistic, or very nearly so. And the texture is not isolated to the individual points in the point cloud, like with a tripod-based scanner.”

“Instead, the texture fills the spaces between those points. A side benefit of filling in the gaps comes when you examine the vehicle from perspectives you didn’t consider when you were at the inspection. Now I’m not limited by the photos I took at the inspection. I can generate, on demand, what look like inspection photos of different aspects of the vehicle.”

Carter continued, “With Leo, we get highly accurate scans that provide more than enough geometry data for any analysis we need to conduct. And then you add in the photo texture to make it real. I remember the first time I zoomed in on the model of a vehicle we captured with our Leo. It was phenomenal. It looked exactly like the vehicle, which is what you want with a digital twin. We weren’t able to generate such high-fidelity models in the past. Not even close.”

Artec Studio screenshot showing the Leo scan of the Dodge Minivan

Having a digital twin of the vehicle that’s lifelike down to the smallest detail has become an expectation for Carter and his team since they started using their Leo. “When we sit down to go through the Leo scans in Artec Studio, it’s like being right there alongside the vehicle exactly as it looked during the inspection. We can visualize the evidence from any perspective we want, and we can measure it with exceptional accuracy,” Carter said.

Inspecting vehicle damage in Artec Studio

Carter explained how they use data from their Leo: “After compiling scans of a damaged vehicle, we align undamaged portions with a 3D model or scan of a similar undamaged vehicle. Comparing damaged and undamaged sections helps determine the extent of crush, providing insights into collision forces and energy absorbed.”

“We can estimate change-in-velocity (delta-V) from absorbed energy and impact speed with enough other evidence. Additionally, we compare damaged and undamaged vehicles with collision analysis to assist experts studying injury causes and vehicle design impact.”

From 3D scan to biomechanical injury analysis

Origin Forensics also uses the data from Leo for biomechanical injury analysis. Here Carter and his team translate the outer crash event to the events involving the occupants inside the vehicle. A key aspect of the analysis focuses on determining how the occupants were interacting with the interior features of the car from the moment of impact onwards.

In Carter’s words, “We match up the occupant’s injuries to the elements of the passenger compartment that caused them, and determine whether any of the safety features there failed to perform as expected, whether that’s airbags, seat belts, or something else that was designed to mitigate injury. Could something have been designed or manufactured differently to prevent those injuries? We analyze every possible scenario, from beginning to end.”

Carter and Rothwell reviewing Leo scan data of the 2014 Dodge Charger in Artec Studio

During initial consultations with a client, in-person or over the web, Carter can share his screen and bring up the digital twin his team generated with their Leo, pointing out and explaining any relevant details.

Inspecting the Charger’s crush deformation patterns using Artec Studio’s surface distance mapping feature

Carter explained, “Navigating a detailed 3D model complements 2D photos, which are fixed in perspective and time. Clients often ask about specific vehicle aspects, and we can virtually show them as though standing beside it or viewing a photo from that angle.”

Using Leo scans for comprehensive vehicle damage reports

After consulting with a client, we may need to submit a report or testify during a deposition or trial. Creating exhibits to help readers or jurors understand the vehicle damage is often a crucial part. And the 3D models generated from Leo scans provide the assets needed to create compelling visual exhibits.

Forensic Technician Kyle Rothwell, Origin Forensics’ in-house expert on Leo, described how he processes the Leo scans in Artec Studio software: “After importing our Leo scans, first I run Global Registration on a group of scans, then Outlier Removal on each of the groups, after which I align them.”

Rothwell processing the Leo scans of the 2014 Dodge Charger

“Then I clean up any stray geometry data, such as bits of glass, dirt, asphalt, etc. After registering, aligning, and cleaning the raw data, I set the ground plane and orient the object to match the vehicle’s right-side view.”

Rothwell continued, “Then I run a Sharp Fusion, followed by a Fast Mesh Simplification. For a vehicle, a mesh density of about 2 million to 5 million triangles is appropriate for what we need. From there, I will apply the texture information for export and select the reduced glare. I normally use an 8K texture map to retain the smaller details. Then the model is ready for export, usually in .OBJ format with .PNG texture.”

3D digital twins of vehicles: even better than the real thing

Although most cases Carter’s team handles are settled or dismissed before trial, the Leo enables their long-held dream: presenting a true-to-life virtual vehicle representation to the jury.

“With the digital twin,” Carter explained, “I can zoom, rotate, and display damage from any angle or magnification requested. This evidence reflects exactly what I observed during my inspection.”

Preparing for inspection in Artec Studio: merging the Charger scan with an exemplar 3D model of the same vehicle

“In the near future,” Carter said, “juries might use their own monitors or VR goggles during presentations, enhancing Leo’s scan data impact. We could guide them around or inside a vehicle, highlighting key aspects as needed.”

“In the past, we had to bring the car to the courthouse and take the jury outside to see it. This process was expensive and offered no guarantee the court would allow it. With data from our Leo, we now bring the car into the courtroom and let jurors walk around it virtually.”

Using Artec Studio’s surface distance mapping to visually inspect the crashed Charger’s damage

While comparing handheld 3D scanners online, Carter discovered the YouTube channel of Artec Ambassador Digitize Designs. He contacted Bo Helmrich, the company’s 3D Scanning Expert, who introduced the Artec Leo through scanning videos and vehicle scan data.

To demonstrate how effectively the Leo would meet their needs, Helmrich scanned his Toyota Highlander’s exterior in 32 minutes. 90 minutes later and the scans were processed and ready to go. Carter remembered his first impressions of the 3D model he received:

“I was amazed by the geometric detail and textures, which are crucial for the important work we do. Now, without the quality of the underlying 3D data being so high, the textures wouldn’t be nearly as effective. Because both the textures and the 3D data contextualize each other.”

Carter explained further, “If for any reason the polygonal mesh is out of whack, distorted, or warped, even in the least, no amount of amazing texture is going to save that. Fortunately, Leo delivers brilliant results in both categories. We saw it then and we see it in every single project we use it for today.”

Learning to use the Leo, from unboxing to scanning in minutes

Carter and his team received remote training on operating the Leo scanner and Artec Studio software after purchasing their Leo. Rothwell commented on his experience with this:

“Learning how to use our Leo on smaller objects like a Pelican case was a joy. Right out of the box, Leo was ready to go and generating detailed models in just a few minutes. Scanning larger objects was a bit more challenging at first, so I found a different approach.”

He explained, “Dividing the project into smaller chunks worked best by scanning each vehicle section separately and loading them into Artec Studio. Now we have consistent and accurate results every time.”

When asked about Leo’s impact, Rothwell said, “Looking back at our previous scanning methods, there’s truly no comparison.”

Forensic Technician Kyle Rothwell scanning a vehicle with Artec Leo

He continued, “The Leo is on an entirely different level. Operationally, it’s the feedback you get while scanning (real-time review), the ability to capture fine details, and the quality of color texture information that absolutely set the Leo apart.”

Carter and his team, with their engineering expertise and reconstruction experience, often handle accidents requiring deep knowledge of crash physics. Further, they frequently extend their analysis to evaluating the injuries sustained by a vehicle’s occupants.

This is why major companies like Chrysler, Ford, Honda, Jeep, Nissan, Toyota, and agencies across the U.S. trust Origin Forensics. Their in-depth investigations, detailed reports, and honest consultations bring existing clients back, and drive frequent referrals to new clients.

Origin Forensics’ guiding motto is “Veritas, Fidelitas, Claritas” (Truth, Faithfulness, Clarity). Their motto reflects their mission to uncover the truth, use advanced technology for evidence, and present findings clearly.

Carter highlighted Leo’s importance, stating, “I aim to advance forensic accident reconstruction by using the best technologies for exceptional services. That’s why I chose the Artec Leo. It gives us that edge beyond anything else on the market.”

We hope you found this article useful, if you wish to see the original article please visit the Artec 3D website.

FAQ: Using 3D Scanners in Accident Reconstruction

1. What makes the Artec Leo 3D scanner ideal for accident reconstruction?

- The Artec Leo provides portability, speed, and high-resolution scanning, enabling forensic teams to quickly create detailed vehicle digital twins. Real-time feedback ensures you capture all critical details during the scanning process.

2. How does 3D scanning improve the accuracy of accident reconstructions?

- The Artec Leo 3D scanning technology captures intricate vehicle details, both exterior and interior, to create a precise digital model. You can use this model to analyse damage, assess safety feature performance, and conduct biomechanical injury analysis with exceptional accuracy.

3. Why is the Artec Leo preferred over traditional tripod-mounted laser scanners?

- The Artec Leo is wireless and handheld, making it more flexible and faster to use than traditional tripod-mounted scanners. It reduces the time needed to complete a vehicle scan and allows immediate rescanning of missed areas for thorough data.

4. How does texture fidelity impact the effectiveness of 3D scans in forensic investigations?

- High-fidelity texture data enhances the digital twin’s realism, offering crucial visual details for analysing vehicle damage and injury contributions.

5. Can 3D scanning data be used in court presentations?

- The Artec Leo creates digital twins, generating compelling court exhibits. These models let jurors explore vehicles from any angle, offering better understanding than traditional media.

6. How does 3D scanning assist in biomechanical injury analysis?

- By creating a detailed digital model of the vehicle, experts can match occupant injuries to specific features inside the vehicle. This helps determine if any safety features failed and contributed to injuries, offering valuable insights for investigations and litigation.

Central Scanning 3D Scanning Experts & Ambassador For Artec 3D

Central Scanning has been a leading 3D scanning technology company for automotive in the United Kingdom since 2006. We are Artec Gold Certified Ambassadors and resell 3D scanning equipment from Artec 3D, ZEISS, and GOM. Furthermore, as the UK’s first resellers of Artec 3D systems, we have extensive expertise in using these adaptable scanners. Therefore, we offer bespoke training and support packages and can tailor our bids to meet your specific requirements.

If you are looking for assistance with Artec 3D products or have any questions about our 3D Scanning Services, get in touch today. Call us on: 01527 558 282.