Curated Content Summary: Did you know that to create bespoke props for their faces, Saturday Night Live often used life casting. However, with the need to keep a social distance it became an issue. Consequently, they discovered 3D printing and 3D scanning as a solution. This article, originally found on Artec 3D, written by Loretta Marie Perera discusses how they found the solution and the process of using the Artec Space Spider to scan each cast members within only a few minutes.

Scanning ‘Ted Lasso’ star Jason Sudeikis (Credit: Amy Tagliamonti)

What does an average Saturday night look like? If you’re Louie Zakarian, long-term makeup artist of Saturday Night Live, it likely involves preparing a host of actors for SNL’s signature comedy sketches, including everything from makeup to hair, props to costumes, and a fair amount of chaos. They are, after all, live from New York.

And while Zakarian has been at it for decades – the makeup department head has eight Emmy awards and 25 years to show for it – recent changes have demanded new ways. At the forefront of all this is 3D scanning.

“With Covid-19 now being an issue, I was trying to figure out a way to be more Covid compliant,” he said. “For a traditional lifecast, I would need two artists to cast one actor – that’s a lot of physical contact, and for 20-30 minutes.”

But with the option of 3D scanning now in play, being able to capture every detail of an actor’s face requires just the actor and the person scanning, with the social distancing issue sorted. “Now one artist can scan one actor in under 10 minutes, and with no physical contact,” Zakarian added.

While he had considered using 3D scanning for some time, it was only upon getting acquainted with Artec Space Spider that Zakarian found satisfactory results. “I looked into scanning for a while, but I wasn’t finding the resolution that I needed,” he said. “That was until I saw Space Spider 3D models online.”

Finding 3D scanning solutions

Working with a representative from Artec Ambassadors TriMech, a solution was reached.

“When I heard SNL, my first thought was…”Saturday Night Live? What could they do with a scanner?” said Josh Watte, TriMech manager. “After talking with Louie we had a firm grip on what he wanted and why he wanted it. With all the COVID restrictions it really made sense to have a more hands-free approach to their processes.”

“My standard question for customers who want to scan faces is ‘Do you want to be able to see people’s pores?’” said Applications Engineer Brian Metzger. While most people say no, Zakarian was the rare customer who was adamant about getting as much small detail as possible for planning elaborate makeup and prosthetics often used in SNL sketches. The level of detail and resolution required made Space Spider the ideal choice. “His life casts showed creases and pores, and he likes to match the makeup to that level of detail,” Metzger confirmed.

An ambitious 3D scanner destined for greater heights, the Artec Space Spider was first designed for use on the International Space Station. Promising high resolution and steadfast color, the Space Spider is ideal for scanning anything from small objects with great precision, to large objects with intricate details. The Space Spider was made for brilliantly capturing difficult angles and complex geometry, which makes it an ideal scanner for the facial scanning needed on the show.

One of SNL’s characters – President Joe Biden played by comedy superstar Jim Carrey – was first in line. “After our first training session I told Louie to practice, and he said ‘Great, we’ve got Jim Carrey coming in tomorrow, and I’m supposed to scan him first!’” recalled Metzger.

“He was one of the first people I needed to make prosthetics for,” Zakarian explained. “Instead of doing a traditional lifecast of Jim, I just did a 3D scan using Space Spider, printed a lifecast of his nose, and then I sculpted on that and made my prosthetics for him to be Joe Biden.”

A quick and easy process

The new process is a relief to cast members as well – while it is able to capture details directly from the face being cast, life-casting is an involved process that requires molding, casting, and the person in question to stay still for some time – and as you can imagine, to keep their eyes shut during the process which can last anywhere from 20 minutes to several hours.

“Jim was very relieved when I told him I’d be able to just scan him instead of needing to do a traditional life cast!” Zakarian recalled.

Now, beyond actors that require specific props, all hosts and actors are scanned. “I’ve been doing that with my entire cast now,” he said.

Louie Zarakian holding a freshly printed face of SNL cast member Sarah Sherman (Credit: Amy Tagliamonti)

Normally, a lifecast wouldn’t be able to be done until a Thursday or a Friday, which leads to very tight timing before the live show on Saturday. Now, a quick scan of hosts when they come in for a photoshoot on Tuesday is all it takes.

“When the hosts come in for their photoshoot on Tuesday, I just grab them for five minutes and do a quick face scan of them,” Zakarian said. “So, if I find out on Wednesday night (when table reads, or read-throughs, are typically done) that we have to build prosthetics, I don’t have to wait until when they come the next day for life-casting. I can start printing their face, and on Thursday morning I have them printed and ready to go.”

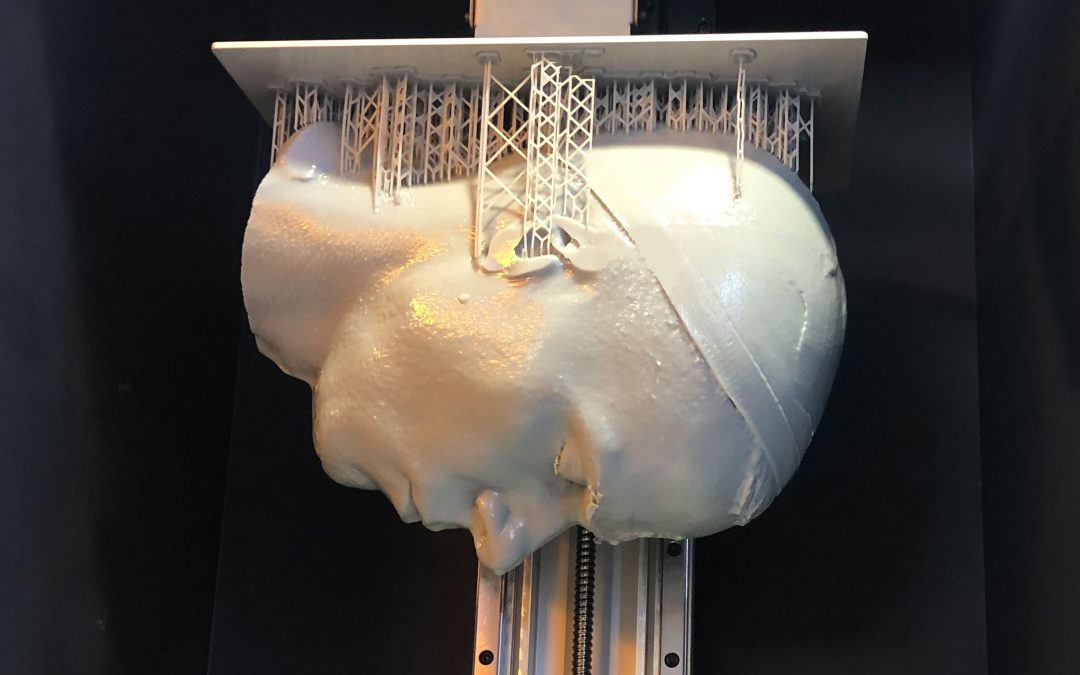

While the scanning is done in minimal time, printing is the next stage of the process, and it is this that takes the most time. “I have a few resin printers so I cut up the file into pieces and print them on them,” Zakarian explained. In Carrey’s case, a full lifecast was printed – that took about 17 hours. “I set it to go at 9 PM and it was ready by 2 PM the next afternoon. I also sliced just his nose into the side of the mold I would need and printed that one separately,” he said. “That one was a 7-hour print so I had it ready for me to work on in the morning when I got in.”

Printing ‘Bohemian Rhapsody’ star Rami Malek (Photo by Louis Zakarian)

While this process takes time, Zakarian says that its advantages outweigh the time spent. “In the past the cast would take 20-30 minutes, and from there it would be sealed and prepped for another 30 minutes. Plaster would be poured into that mold and an hour after that we would have the positive to work from,” he said. “The new resin 3D printing takes a bit longer, but the advantage of minimal contact has been the best thing about it.”

And while 3D scanning has found its way onto the stage and behind the scenes with some of America’s biggest names, the opportunities don’t stop there. “I have hundreds of cast lifecast in my mold room at NBC that take up an enormous amount of space,” said Zakarian.

“But now with the Space Spider, I’ve been scanning all the plaster casts and storing them onto a hard drive, making it possible to empty out my storage space and still have my stock of lifecast for reference, or to work on if a person returns to host the show.”

“There’s something special about working with a behemoth like SNL,” said Matte, who grew up watching the show and remains a fan today. “To say I’m excited and proud to call them a valued customer of mine now is an understatement.”

And for Zakarian, more opportunities may yet present themselves.

“I’m constantly finding new ways to put the Space Spider to use,” said Zakarian. “It’s been great! It’s working out perfectly, and it’s everything that I was hoping it would be.”

We hope you found this article useful, if you wish to see the original article please visit the Artec 3D website.

CENTRAL SCANNING 3D SCANNING Specialists & AMBASSADOR FOR ARTEC 3D

Central Scanning is a leading West Midlands company supplying 3D printing and 3D scanning services to a wide range of industries. As Artec Gold Certified Ambassadors and resellers of 3D scanning equipment from Artec 3D, ZEISS, and GOM, we have extensive knowledge of how to utilise these adaptable 3D scanning systems.

If you are looking for assistance with Artec 3D products or have any questions about our 3D Scanning Services, get in touch today. Call us on: 01527 558 282.