Summary. Understanding the accuracy of 3D scanners is complex. Rather than fixating on specifications, focus on whether a scanner solves your problems effectively. Choose the right scanner for your purpose and environment.

It is understandable, when choosing one, that you’d want to know how accurate are 3D scanners. But the concept of accuracy in 3D scanning is not a straightforward one.

This is because accuracy may not be what you think it is in a 3D scanner.

Is There A Standard For Accuracy In 3D Scanners?

Normally, to understand the accuracy of something, you’d need a common standard to work off.

In 3D scanning, however, this standard does not exist.

The accuracy spec for a tripod-mounted 3D scanner could be 2cm. Therefore, the scanner will return measurements within 2cm of the actual dimensions it is recording.

But if you compare this figure with another type of scanner, say a handheld model, it does not take into account other critical factors which will determine the accuracy of your scan.

When replicating an object, you may need to scan it several times to capture every angle. Once you’ve done this, you can merge all these registered parts into one.

What happens if you use this same process to arrive upon the accuracy specification of a scanner?

Is this methodology the same for different models of 3D scanner, and if so, where are they measuring the zero point of the scanner? And what characteristics of the object they are scanning might influence the readings?

Why Is Reflectance Important?

Even with 3D scanning technology that has highly accuracy specifications, you can arrive at very different results depending on whether a surface is reflective or not.

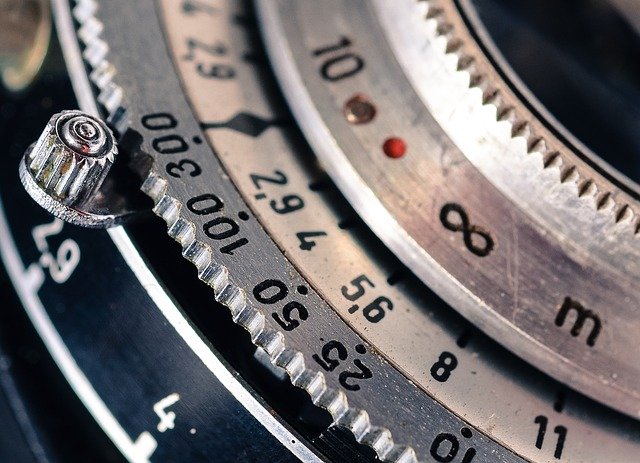

Dark, shiny and transparent surfaces are difficult to scan. Optical light-based 3D scanners use light as a source of projection. They capture images of patterns as they hit the surface of an object and deform. These images calculate the distances between the scanner and the object and are the basis for the point clouds that enable production of a 3D digital replica.

Actions can be taken to improve the scanning surface, such as using sprays. However, these are usually temporary and only improve the surface so much.

But with certain reflective surfaces, the light patterns become distorted, causing interference.

On these shiny surfaces, light scatters and bounces in directions that are hard to control.

What Is Accuracy In The Field?

Even if you took issues like reflectance into account and were able to standardise accuracy specs across 3D scanning devices, there is still the issue of accuracy in the field.

There are different ways to approach 3D scanning. For example, do you measure off the point cloud points themselves? Or first model a plane over them and measure from that?

Different scanning methods will derive a measurement from a scan, but will give different results.

Therefore, accuracy becomes something that is not a defined figure, but something subject to methodology.

Other elements can affect the accuracy of scanning in the field, such as the complexity of the environment in which you are scanning.

How tightly registered are the multiple scans you are taking when you’re determining accuracy?

What if there is an error midway in the process, which skews the results?

FAQ: 3D Scanning Black and Reflective Materials with Central Scanning

Why is it challenging to 3D scan black and highly reflective materials? Black and reflective surfaces, such as chrome, are difficult to scan because they reflect the light from the scanner in various directions, causing high noise levels and distorted results. This often leads to incomplete or inaccurate data capture.

How does Central Scanning overcome the challenges of scanning black materials? Central Scanning uses advanced 3D scanning technology like the GOM ATOS Q and ZEISS T-Scan hawk 2, which are specifically designed to handle challenging surfaces. The GOM ATOS Q utilizes blue light technology to effectively scan black surfaces, while the ZEISS T-Scan hawk 2 excels at capturing highly reflective surfaces.

What makes the GOM ATOS Q ideal for scanning black materials? The GOM ATOS Q scanner is equipped with powerful blue light technology and an advanced software infrastructure that allows it to scan black surfaces with precision. It offers flexibility for complex measurement tasks and is especially effective for small to medium-sized parts.

When should I use the ZEISS T-Scan hawk 2? The ZEISS T-Scan hawk 2 is ideal for scanning extremely reflective surfaces, like chrome. Its laser-based technology ensures high-quality scans, even with the most challenging materials.

How do reference markers enhance the accuracy of 3D scanning? Reference markers help the scanning software accurately triangulate the part’s position in 3D space, even when the part is rotated. This ensures that all details on all surfaces are captured with high precision, allowing for accurate alignment of the scans.

Should Accuracy Be About Problem-Solving First?

The simplest way to define how accurate 3d scanners are, is whether it enables you to capture a scan that will solve your problems or answer your questions.

In other words, the accuracy of your scanner should align with the environment you’re using it in, the object you’re scanning, and the end-purpose of doing it in the first place.

Therefore, if you choose your 3D scanner purely on the basis of specifications for accuracy, you could be missing out on the right scanner for your intended purpose.

This is a more flexible approach, because it focuses on the functionality of the 3D scanner, and making sure this matches what you want to achieve with it.

Accuracy, therefore, does not need to be a fixed standard. But, rather good enough to achieve the results you are looking for.

A less expensive handheld model, for instance, may be the right choice for giving you the data you need for your purposes. What it loses in accuracy, it gains in flexibility and adaptability to the environment you are using it in.

If your tripod scanner boasts millimetre-accuracy, this won’t necessarily be an advantage if it will mean that it takes you weeks to capture your entire project. Whereas a handheld model will do the job much faster.

When selecting a scanner, always weigh up its accuracy against your specific needs. In addition, how practical a piece of kit is, that you need it to be in the field.

For more information on how accurate are 3d scanners, please contact us, to discuss your 3D scanning requirements in detail.

For guidance on choosing the most suitable 3D scanner, consult Artec’s advanced solutions to match your specific project needs.