Exploring Material Choices in 3D Printing at Central Scanning

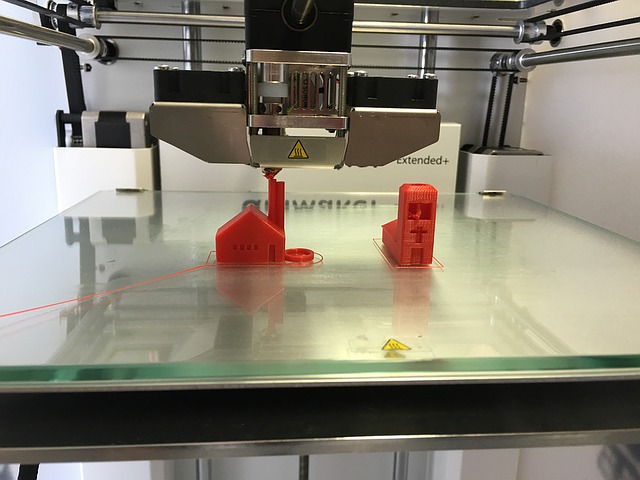

When it comes to 3D printing services, the choice of material is crucial, as different plastics offer varying benefits depending on their intended environment. Central Scanning, a leader in 3D printing and scanning in the UK, provides insights into the types of materials used in 3D printing and their specific applications.

Environmental Suitability and Material Selection

The selection of materials in 3D printing is heavily influenced by their environmental suitability. For instance, some plastics have lower melting points and may soften at lower temperatures, affecting their application scope.

PLA (Polylactic Acid): Strength with Limitations

PLA is a strong and rigid filament, ideal for a range of applications. However, its tendency to soften at temperatures as low as 60°C limits its use in high-temperature environments. This characteristic makes PLA less suitable for objects that might be exposed to heat, like in a hot car during summer.

Nylon: Flexibility and Durability

Nylon offers more flexibility compared to PLA and excels in durability. It’s less likely to tear, making it an excellent choice for parts requiring impact resistance. Nylon’s robust nature makes it preferable for certain applications over PLA.

ABS (Acrylonitrile Butadiene Styrene): Popular Yet Challenging

ABS is a common choice in 3D printing due to its durability and reasonable temperature resistance. However, its fumes can be a concern, particularly for hobbyist enthusiasts, making it less popular in non-professional settings.

PETG (Polyethylene Terephthalate Glycol): A Balanced Alternative

PETG stands out as a viable alternative to ABS, combining durability with safer usage due to its non-carcinogenic fumes. While it may not match ABS’s temperature resistance, PETG offers a balanced tradeoff between performance and safety.

FAQ: Material Choices in 3D Printing with Central Scanning

Why is the choice of material important in 3D printing? The material you choose for 3D printing significantly impacts the durability, flexibility, and environmental suitability of the final product. Choosing the right material is critical for successful outcomes, as different materials suit different applications better.

What are the key differences between PLA and Nylon in 3D printing? PLA is strong and rigid but softens at temperatures as low as 60°C, limiting its use in high-temperature environments. Nylon, on the other hand, offers greater flexibility and durability, making it ideal for parts that need to withstand impact and wear.

Why might someone choose PETG over ABS for 3D printing? PETG is a balanced alternative to ABS, offering durability without the hazardous fumes associated with ABS. While it may not be as temperature-resistant as ABS, PETG provides a safer option for environments where fumes could be a concern.

How does Central Scanning help in selecting the right material for my 3D printing project? Central Scanning’s experts provide tailored advice on material selection based on your project’s specific requirements, ensuring that you choose the best material for optimal results.

Can Central Scanning handle complex 3D printing projects with multiple material needs? Yes, Central Scanning has the capability to handle complex projects requiring a range of materials, offering high-quality rapid prototyping and 3D printing services to meet diverse needs.

Central Scanning | Your Partner in 3D Printing Excellence

Located in Worcestershire, West Midlands, Central Scanning is at the forefront of 3D printing and scanning services in the UK. We offer high-quality rapid prototyping and 3D printing, utilising a diverse range of materials to suit various project requirements. Equipped with advanced 3D object scanners, portable 3D scanners, and professional 3D scanners, we are prepared to handle any project challenge. For expert advice on your next 3D printing project, contact us at 01527 558 282, or fill out our contact form. Our team is ready to assist you with any questions and guide you towards successful project completion.